- upload bom file

- +86 0755-82770375

- info@onepcba.com

- Compare Products

- Change Location:

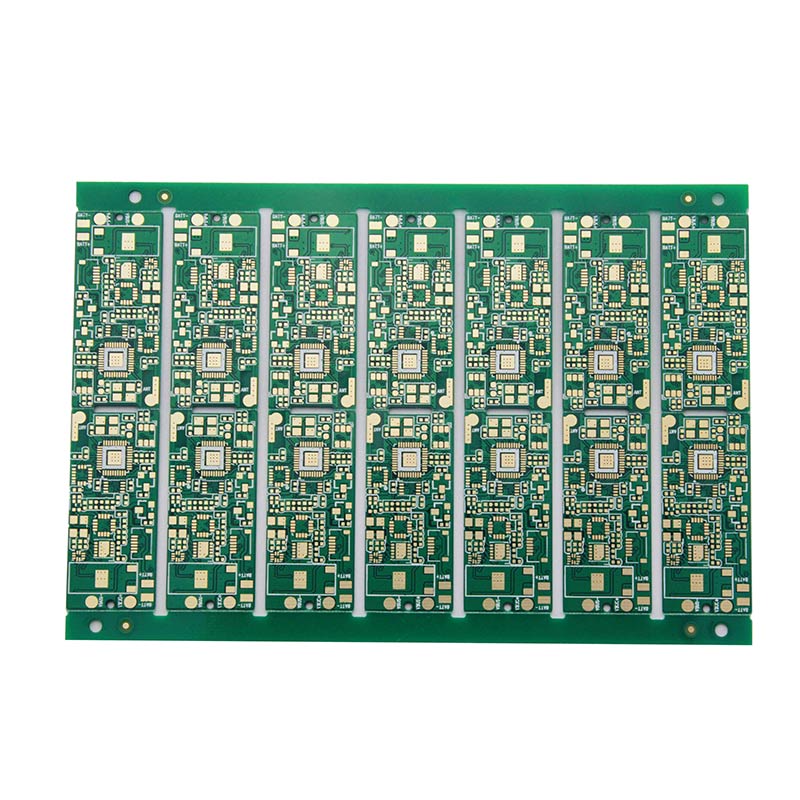

18layer High frequency and high speed PCB

Layer: 18

Thickness: 1.2 mm

Material: ISOLA

Construction: 2+16+2 HDI PCB

Copper: Outer 3 OZ, Inner 2 OZ

Surface: ENIG

Application: Automotive Electronics

Minimum blind/Buried hole: 0.15 mm/0.1mm

Minimum line width: 3.3mil

Line spacing: 3.3mil

Product Details

When manufacturing high-frequency PCB, the commonly used plates are Rogers, ISOLA, Taconic, Panasonic, Taiyao, etc.

DK of high frequency PCB should be small and stable, usually the smaller the better. High frequency PCB will cause signal transmission delay. DF should be small, which mainly affects the quality of signal transmission. The smaller DF can reduce the signal loss accordingly. In a humid environment, the water absorption rate is low and the water absorption capacity is strong, which has an impact on DK and DF.

The thermal expansion coefficient of high-frequency circuit board should be the same as that of copper foil as much as possible, because high-frequency circuit board may cause copper foil separation under the condition of alternating cold and hot, and should be the same as that of copper foil as much as possible, so as to ensure the perfect performance of high-frequency circuit board. High frequency PCB has the characteristics of heat resistance, chemical corrosion resistance, impact resistance, peeling resistance, etc.