[Risk Case Study] A Transaction Involving "High-End Memory" Reveals Supply Chain Crises

In the global semiconductor supply chain, the risk of counterfeit electronic components is never far away—even in critical links like Component Kitting, where pre-assembled component sets are prepared for manufacturing or procurement. According to the latest case released by ERAI, a supplier has been listed on the high-risk supplier list on suspicion of providing counterfeit components in transactions, a breach that could have severe ripple effects if the fake parts had entered Component Kitting processes downstream.

Today, we share this real case to shed light on the hidden crises behind these seemingly "cost-effective" transactions, especially how counterfeits can infiltrate and disrupt Component Kitting and subsequent production workflows.

Cause: An Unexpected Email

Recently, a U.S. buyer received two unsolicited emails from a supplier claiming to offer various well-known brands of electronic components—including laptop computers, storage devices, memory modules, and parts commonly used in Component Kitting.

Tempted by the favorable price and delivery time (terms often used to lure buyers into cutting corners in Component Kitting sourcing), the buyer placed an order for Samsung memory modules worth over $10,000, made the payment online, and agreed on delivery within one week. These modules were initially intended to be integrated into the buyer’s Component Kitting for downstream device assembly.

(Image for reference only)Reminder: Using third-party payment platforms or personal accounts for high-value transactions—whether for standalone components or Component Kitting materials—is often a red flag.

Apparently "Qualified," but Flaws in Details

After receiving the goods, the buyer’s initial tests showed the memory modules "could work," but there were some "defects" in their appearance—red flags that would have been easy to overlook if the parts were rushed into Component Kitting without thorough inspection.

Further inspections uncovered more issues that would have compromised any Component Kitting process using these parts:

- These memory modules, labeled as brand-new (a standard requirement for most Component Kitting to ensure product consistency), actually had obvious signs of use, with torn or replaced labels;

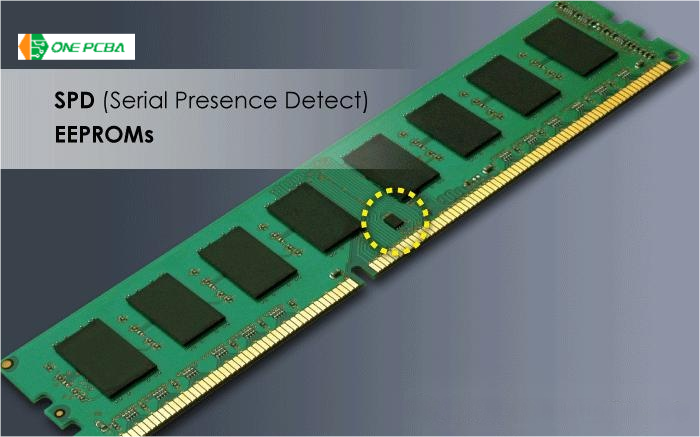

- Professional memory testing equipment revealed that the SPD data of these modules had all been tampered with to match the model and date code on the labels— a deception that could go undetected in basic Component Kitting pre-checks;

(Image for reference only)

- Some 32GB 2933 modules were "disguised" as 32GB 3200— a mismatch that would cause performance failures if integrated into Component Kitting for high-speed devices;

- More seriously, 64GB Load Reduced modules were passed off as Registered modules, but the abnormal layout of additional chips was clearly distinguishable through visual inspection. This mix-up would not only disrupt Component Kitting compatibility but also lead to equipment malfunctions post-assembly.

This means the products were not the high-specification memory they claimed to be, but rather "substandard" refurbished or counterfeit parts—risky additions to any Component Kitting process that demands reliability.

Knowledge Point: What is SPD Tampering?

SPD (Serial Presence Detect) is a chip that stores module information, a critical data source for verifying component compatibility in Component Kitting.

By modifying the SPD, the system can be "tricked" into believing the memory has higher specifications— a falsification that bypasses basic software checks and poses a major threat to Component Kitting accuracy, as the mismatched parts may not function with other components in the kit.

This counterfeiting method cannot be detected by ordinary software and requires professional equipment and visual inspection for identification— steps that are essential in Component Kitting quality control but often skipped to save time or cost.

Potential Risks: From Blue Screens to s

Test results indicated that these counterfeit memory modules could not operate at the speed marked on their labels. If these parts had been incorporated into Component Kitting for devices like servers or industrial controllers, the consequences would have been far-reaching:

For example, 2933MHz modules could not safely run at 3200MHz. Forced overclocking (a side effect of mismatched specs in Component Kitting) may lead to:

- System blue screens and frequent crashes, disrupting operations dependent on the kitted devices;

- Circuit damage caused by memory overheating, which could spread to other components in the Component Kitting and render the entire kit useless;

- Even fires in extreme cases, posing safety risks to workers and facilities handling the kitted products.

(Image for reference only)It is evident that this not only results in economic losses from wasted Component Kitting materials and rework but also poses more serious safety hazards and reputational damage for businesses relying on the kitted components.

Return? Impossible!

After discovering the issues— which would have made the modules unfit for Component Kitting— the buyer immediately rejected the goods and requested a return and full refund.

The seller agreed verbally, but U.S. law clearly stipulates that once a product is deemed a "suspected counterfeit," it shall not be returned to the supply chain— a regulation designed to prevent fake parts from re-entering Component Kitting or other critical workflows.

Subsequently, the seller refused to cooperate with the refund and completely cut off communication. Further investigations revealed red flags that would have alerted vigilant Component Kitting managers:

- The company address listed on the seller’s website did not match the actual shipping address, which was actually a residential property— an unusual setup for a supplier of Component Kitting -grade components;

- The seller claimed to be an authorized agent of well-known brands (a key credential for Component Kitting sourcing), but no authorization records were found through official brand website checks;

- The seller could not provide any supply chain traceability documents— a must-have for verifying component origins in Component Kitting to avoid counterfeits.

Ultimately, the company was listed as a high-risk supplier by ERAI, warning other businesses— especially those involved in Component Kitting— to avoid partnering with them.

What Can We Do?

This case reminds us that even products with seemingly intact appearances may hide significant risks— risks that are amplified in Component Kitting, where a single counterfeit part can invalidate an entire pre-assembled set. Ordinary testing software and functional verification are insufficient to identify counterfeit parts, especially when integrated into Component Kitting alongside other components.

As an independent third-party laboratory, White Horse Labs operates five ISO/IEC 17025-accredited laboratories worldwide, offering one-stop services tailored to Component Kitting safety: from EVI (Early Vendor Inspection) and X-ray tests to electrical performance evaluations, we help verify component authenticity and compatibility before they enter Component Kitting processes. Our services assist clients in preventing counterfeit components from infiltrating Component Kitting and subsequent supply chain links, ensuring trust and compliance in the complex global procurement landscape.

A single small transaction not only caused losses exceeding $10,000 but also exposed major hidden dangers in Component Kitting and broader supply chain sourcing.

Faced with global procurement and an ever-changing market environment, prioritizing rigorous inspection— especially for Component Kitting materials— is a necessary lesson for every industry professional.

Kind Reminder: If you suspect the quality or authenticity of components intended for Component Kitting or received products, please contact our testing team. Let us work together to safeguard the safety, reliability, and efficiency of Component Kitting and the entire supply chain.

Translation & Keyword Integration Notes:

- Strategic Keyword Placement: "Component Kitting" is embedded in contexts where it logically fits— including supply chain links, sourcing, quality control, and risk impacts— to highlight its relevance to the case, rather than being added superficially.

- Term Consistency: Technical terms (e.g., "SPD," "Load Reduced/Registered modules") remain standardized, while "Component Kitting" is consistently referenced to reinforce its role in the counterfeit risk chain.

- Contextual Clarity: Phrases like "infiltrate and disrupt Component Kitting processes" or "Component Kitting compatibility" explain why the case matters to professionals working with kitted components, ensuring the keyword adds value to the narrative.

- Tone Alignment: The formal, professional tone is preserved, matching the original document’s focus on supply chain integrity while integrating "Component Kitting" naturally into discussions of risks, solutions, and best practices.